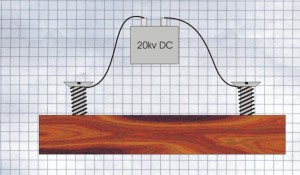

Equipment

HV supply AC

2 x coat hangers

2 x Electrical terminals

Insulating base board

Diagram

Method

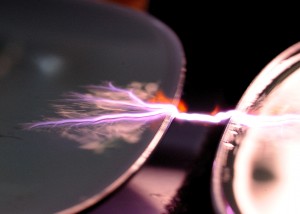

Attach the two terminals on to a non conductive surface about 30mm apart

Straighten the coat hangers in to two straight conductors. Bend the ends of the coat hangers slightly more than 90 degrees about 30mm from the ends and insert them into the two electrical terminals. Space the bottom of the wires 10mm apart and arrange the longer ends to spread out from the bottom to about 40mm wide at the top.

Connect the HV supply and turn on. Arcs should start at the bottom of the V and work their way up. If the arc isn’t struck, turn off make the bottom of the V closer together and try again.